Impressed with Renuka's commitment to quality. The CNC machining components we sourced from them exceeded our expectations. very good company.

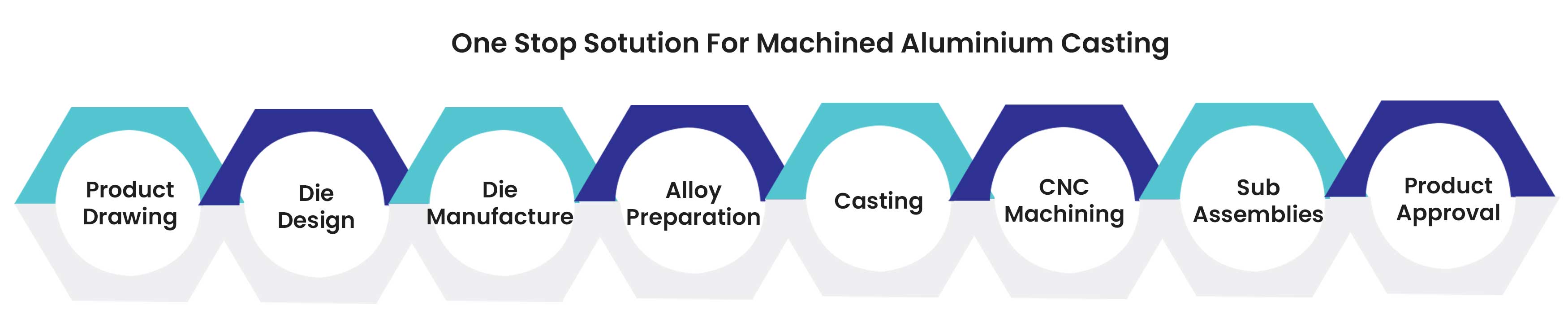

Aluminium Die Casting in India

Renuka Auto Components : Manufacturers of Aluminium Die Casting, Dies & Molds Jigs & Fixtures

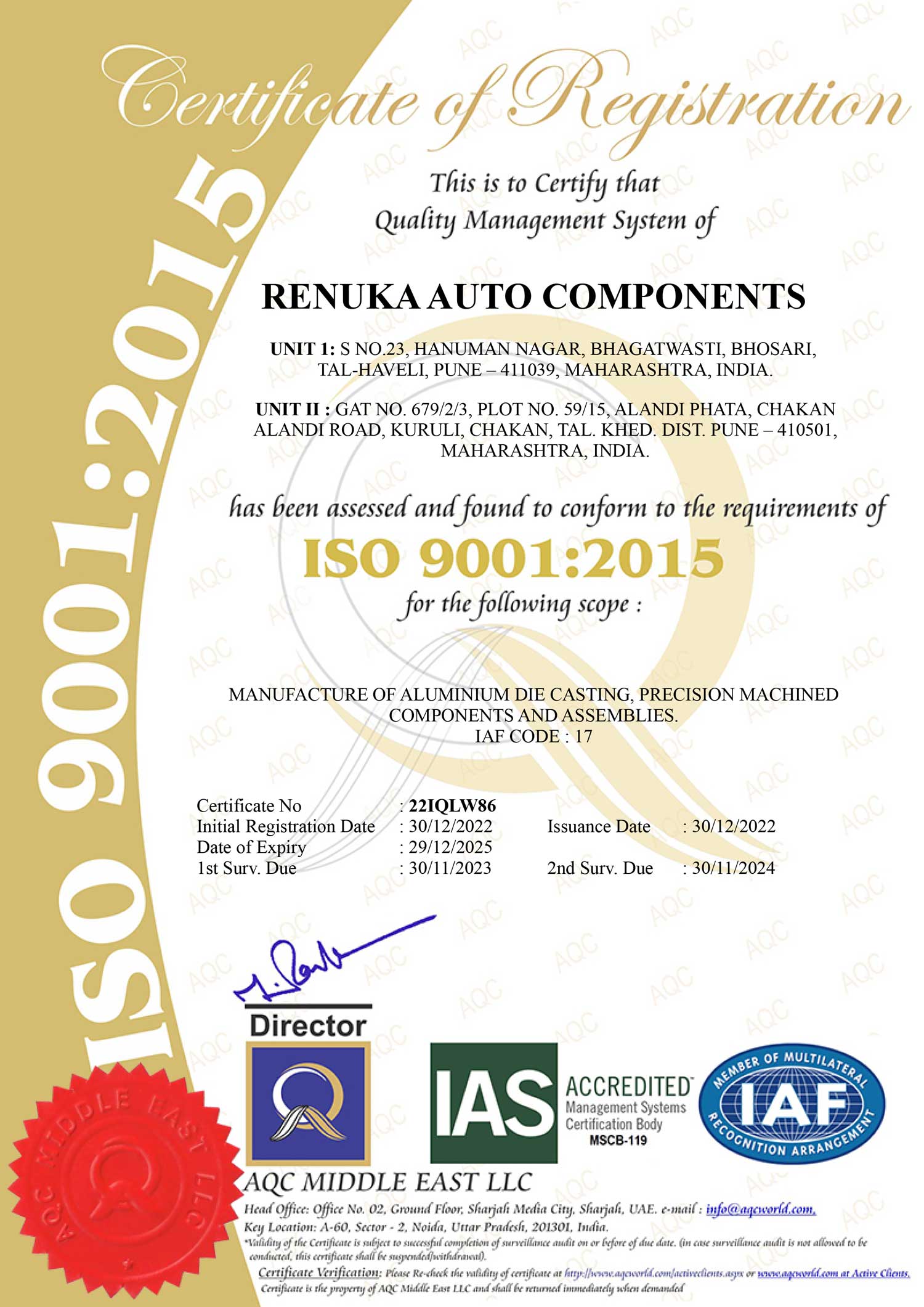

We are ISO 9001:2008 & ISO Certified Aluminium Pressure Die Casting, CNC machine Components Manufacturers in Pune, India and believe in timely deliveries tagged with cost effectiveness and quality aiming to minimum losses and complete customer satisfaction. We manufacture various kinds of starter motor, Tone Wheel, Bolted Pulley, Cooling fins, Unbalance Mass required in automotive products and assemblies.

Quality Policy

Consistent quality is the key factor that has helped RAC to develop into a preferred solution provider.

Every process pass through stringent quality checks to ensure that the end product is upto national & international standards and matches the exact need of the client. Effective quality control measure and inspection is facilitated by Air Guage system and various other essential instruments.

The quality department controls the design and manufacturing process. Statutory & regulatory requirements are followed to meet the social commitment towards all employees which is turn helps to maintain consistency in quality.

Quality Department is well equipped with various sophisticated equipments & follows the quality parameters of ISO 9001:2008.

Our Products

Established in year 1999, we Renuka Auto Components are in to manufacturing of multi-operational precision CNC machined components used in various automotive.